How thick is 100μm? Just about the thickness of an A4 sheet of paper. And it is also the thickness of aluminum laminated film, which is the key material for the lithium battery package, and just such a thin layer of film accounts for nearly 20% of the cost of lithium battery package. What you don’t know is that, as one of the most difficult to process five base materials for lithium batteries, aluminum laminated film is the only material that has not realized mass-production in China. Statistically, the localization rate of aluminum plastic film is only taking up about 40% in the 3C field, and only 25% in the power battery field (the localization rate of the other four base materials is over 90%). The main reason for the failure to achieve localization is that there is still a gap between domestic aluminum laminated film and imported products in terms of punching depth, electrolyte resistance and barrier performance, etc.

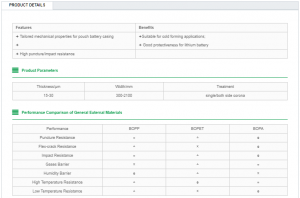

The aluminum laminated film consists of five layers of materials, the outermost layer is nylon layer (BOPA film), also known as the lithium battery film. You can hardly imagine that this layer accounts for nearly two percent of the thickness of the aluminum laminated film and plays the role of the lithium battery “armour”, which needs to have good impact resistance, puncture resistance, heat resistance, friction resistance and insulation properties, which is the key material to determine the performance of the aluminum laminated film punching depth. It is such a thin layer of film, but there was a time when domestic prices were as high as more than 100,000 a ton, and often faced with the dilemma of being out of stock and in short supply. Even today, there are still only a few companies in China that can produce BOPA film for aluminum laminated film

However, there is a Chinese company that is not only able to manufacture, but even the quality of its products has reached a world-leading level. It has not only become a major supplier to the domestic market, but also sold its products to Japan, Europe and the United States. It is one of the “Nylon Film Kings” from Sinolong Advanced Material.

BOPA is recognized as a functional film with high production difficulty in the world, and Sinolong Advanced Materials is one of the few companies in the world that has matured and mastered sequential technology,mechanical simultaneous stretching technology and LISIM simultaneous stretching technology. Its subsidiary Xiamen Changsu has 11 production lines with a production capacity of 85,000 tons per year, ranking first in the world. After years of deep cultivation in domestic and international markets, Sinolong Advanced Materials has become the “Chinese business card” of the BOPA film industry on the international stage.

Post time: Apr-14-2022